Predictive maintenance has emerged as a game-changer in various industries, leveraging advanced technologies to forecast equipment failures before they occur. Among the technologies driving this transformation, Artificial Intelligence (AI) stands out for its ability to analyze vast amounts of data and provide actionable insights. This article delves into the role of AI in predictive maintenance, exploring its benefits, applications, and future potential.

Understanding Predictive Maintenance

What is Predictive Maintenance?

Predictive maintenance is a proactive approach that involves monitoring the condition of equipment during normal operation to predict when maintenance should be performed. This approach contrasts with traditional maintenance strategies like reactive maintenance, which involves fixing equipment after a failure, and preventive maintenance, which schedules regular maintenance irrespective of the actual equipment condition.

The Need for Predictive Maintenance

Industries such as manufacturing, transportation, and energy heavily rely on complex machinery. Downtime due to equipment failure can lead to significant financial losses and safety risks. Predictive maintenance aims to minimize these risks by ensuring equipment operates efficiently and reliably.

The Role of AI in Predictive Maintenance

How AI Enhances Predictive Maintenance

AI in predictive maintenance involves using machine learning algorithms and data analytics to assess equipment health and predict potential failures. Here’s how AI enhances this process:

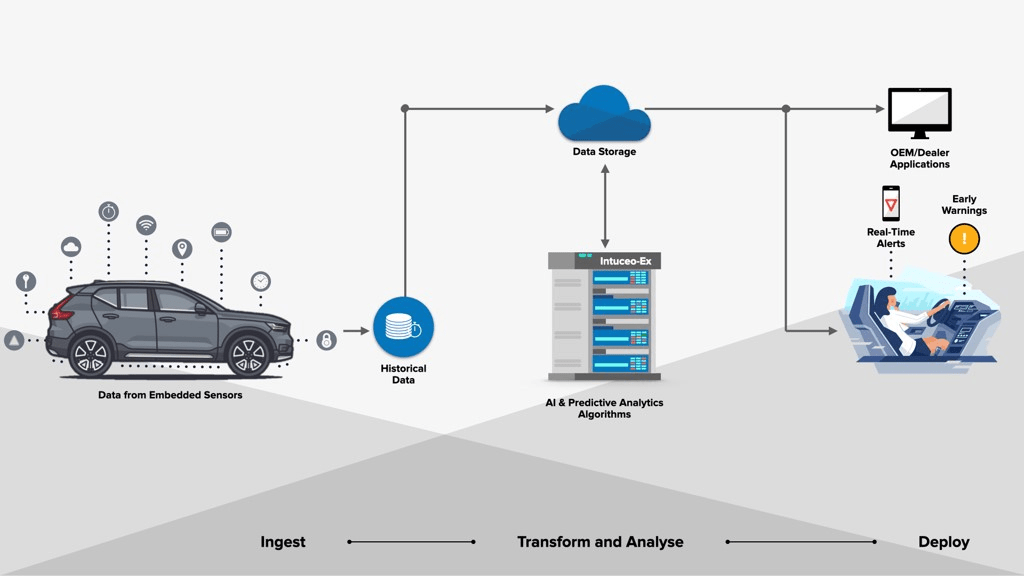

- Data Collection and Analysis: AI systems collect data from various sensors attached to the equipment. This data includes temperature, vibration, pressure, and other operational parameters.

- Pattern Recognition: Machine learning algorithms analyze the collected data to identify patterns and anomalies that might indicate a potential failure.

- Predictive Modeling: AI models predict the remaining useful life (RUL) of equipment and the likelihood of failures, allowing for timely maintenance interventions.

- Continuous Improvement: AI systems learn and improve over time, refining their predictions as more data becomes available.

Key Benefits of AI in Predictive Maintenance

Implementing AI in predictive maintenance offers numerous advantages:

- Reduced Downtime: By predicting failures before they occur, AI helps in scheduling maintenance activities at the most convenient times, reducing unplanned downtime.

- Cost Savings: Preventing unexpected equipment failures reduces repair costs and avoids the expenses associated with emergency maintenance and production stoppages.

- Extended Equipment Life: Regular and timely maintenance based on AI predictions can prolong the lifespan of machinery.

- Enhanced Safety: Predictive maintenance can prevent accidents caused by equipment failures, ensuring a safer working environment.

- Optimized Maintenance Schedules: AI enables more efficient maintenance planning, ensuring resources are used effectively and only when necessary.

Applications of AI in Predictive Maintenance

Manufacturing

In the manufacturing sector, machinery and equipment are subject to constant use, making them prone to wear and tear. AI-powered predictive maintenance helps manufacturers monitor equipment health, detect early signs of potential failures, and schedule maintenance activities without disrupting production.

Energy Sector

In the energy sector, particularly in power plants and wind farms, maintaining the reliability of equipment is crucial. AI helps in monitoring turbines, generators, and other critical components, predicting issues like overheating or mechanical failures, and optimizing maintenance schedules to ensure continuous power supply.

Transportation

For transportation industries, including aviation, railways, and shipping, the reliability of vehicles and vessels is paramount. AI-driven predictive maintenance enables the monitoring of engines, braking systems, and other critical components, ensuring timely maintenance and reducing the risk of in-transit failures.

Oil and Gas

The oil and gas industry operates in harsh environments, making equipment maintenance a challenge. AI systems can analyze data from drilling rigs, pipelines, and refineries to predict failures and optimize maintenance schedules, thus minimizing downtime and ensuring safe operations.

Healthcare

In healthcare, predictive maintenance of medical equipment like MRI machines, CT scanners, and other diagnostic tools is vital. AI helps in monitoring the performance of these devices, predicting potential failures, and scheduling maintenance to avoid disruptions in medical services.

Challenges and Future Prospects

Challenges in Implementing AI in Predictive Maintenance

Despite its advantages, there are several challenges to implementing AI in predictive maintenance:

- Data Quality and Integration: Ensuring high-quality, consistent data from various sensors and integrating it into a centralized system can be complex.

- Algorithm Accuracy: Developing accurate predictive models requires extensive domain knowledge and continuous refinement.

- Initial Investment: The cost of implementing AI technologies, including sensor installation and system integration, can be high.

- Skill Gaps: There is a need for skilled personnel to manage and interpret AI-driven predictive maintenance systems.

Future Prospects

The future of AI in predictive maintenance looks promising, with several trends poised to drive further advancements:

- Edge Computing: By processing data closer to the source (i.e., at the edge), latency can be reduced, enabling real-time predictions and quicker responses to potential issues.

- IoT Integration: The Internet of Things (IoT) will enhance data collection capabilities, providing richer datasets for AI algorithms to analyze.

- Advanced Analytics: Developments in machine learning and analytics will lead to more sophisticated predictive models, improving prediction accuracy and reliability.

- Automation: Combining AI with robotics and automation technologies could lead to autonomous maintenance systems, further reducing the need for human intervention.

Conclusion

AI in predictive maintenance is revolutionizing the way industries manage their equipment. By leveraging advanced data analytics and machine learning, AI enables more accurate predictions of equipment failures, leading to reduced downtime, cost savings, and enhanced operational efficiency. While challenges remain, ongoing advancements in AI and related technologies promise to further enhance the capabilities and benefits of predictive maintenance, driving greater reliability and productivity across various sectors. As industries continue to adopt and refine AI-driven maintenance strategies, the future of equipment management looks increasingly intelligent and efficient.

Leave a comment